MES

- Home |

- MES

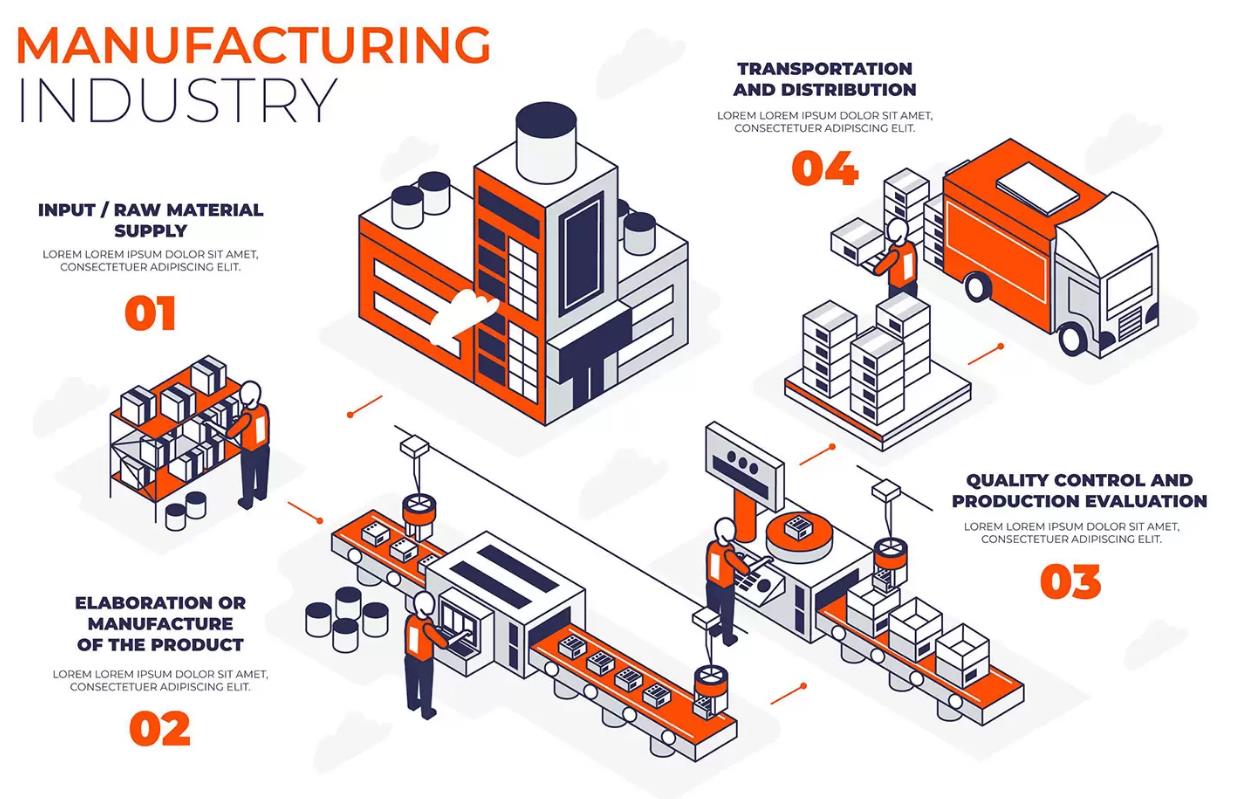

As Omni, we also offer solutions for MES software, which is the bridge between IRP and Production, where many reports are made along with productivity analysis in Industry 4.0.

MES monitors the production instantly and automatically, notifies the responsible persons instantly about the downtime, low performance and quality inefficiencies experienced in production and reports these losses statistically and graphically in detail.

It provides OEE (Total Equipment Effectiveness) infrastructure to increase your production efficiency. It allows you to reduce your downtime-speed-quality losses.

By collecting online production data with sensors, PLCs, etc. devices, LCD screens, e-mail alerts, SMS alerts, it instantly notifies you of any work that goes wrong and increases your productivity by enabling you to take immediate measures.

- General Functions;

- The Planning Officer easily assigns the work orders created in the ERP Software to the machines by drag and drop method from a screen in the form of a Visual Gannt Chart.

- Capacity control can be done here and work orders can be shifted with the mouse.

- Assigned Work Orders are transferred to the Terminals in the Work Centers.

- When the operators start work, they introduce themselves at the Terminal and start the work order.

- Interruptions and their reasons are entered into the terminal by the operators.

- Work orders can be partially or completely finished.

- Finished work orders are saved in ERP.

- All these processes can be monitored online.

- The planning authority can change work order sequences when necessary.

- Through LCD monitors, productivity in work centers can be instantly displayed online to operators and managers.

- Events such as malfunctions, downtime, inefficient operation can be sent as warnings to the desired persons via e-mail and SMS.

- Failure warnings can be sent to maintenance and repair departments via e-mail or SMS.

- Production quantities can be read directly from the machines via sensors and PLCs, eliminating incorrect data and slowness problems.

- Production, Downtime, Speed, Quality data can be reported.

- Filters and ranges can be applied to reports on the basis of Time, Work Center, personnel, Job Code.

- Sorting and filtering operations can be performed on all tables in the software and these tables can be exported to Excel.

- Monitors Energy Expenditures and provides infrastructure for their reduction.

- It provides quick intervention to waste by instantly notifying the expenditures that go beyond the specified ranges via e-mail, sms, dashboards.

- Energy meters are placed on Factory, Department, Machine Basis in accordance with the factory structure.

- What is produced in the machines is recorded.